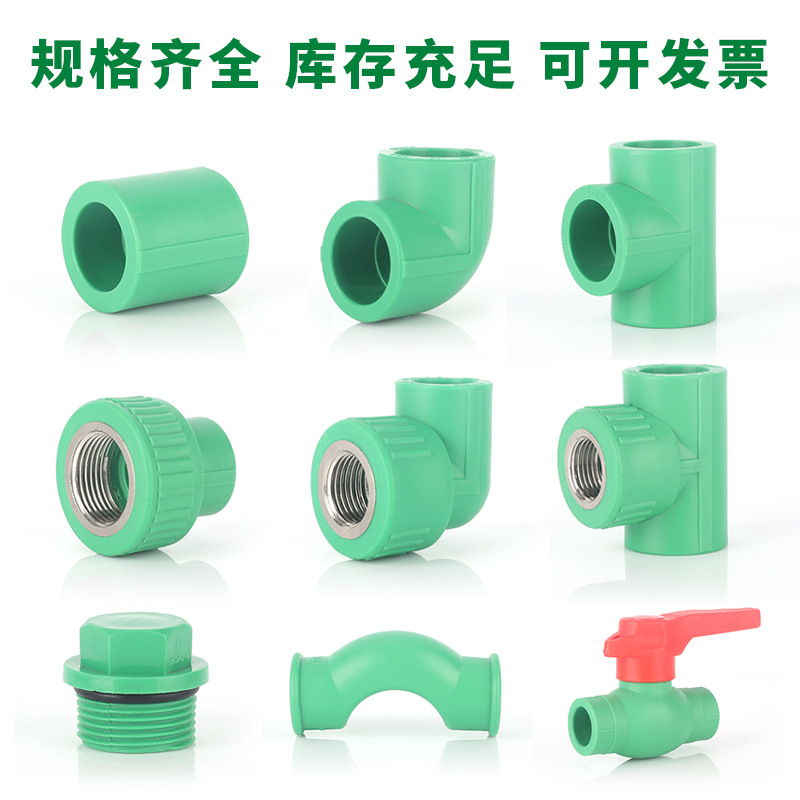

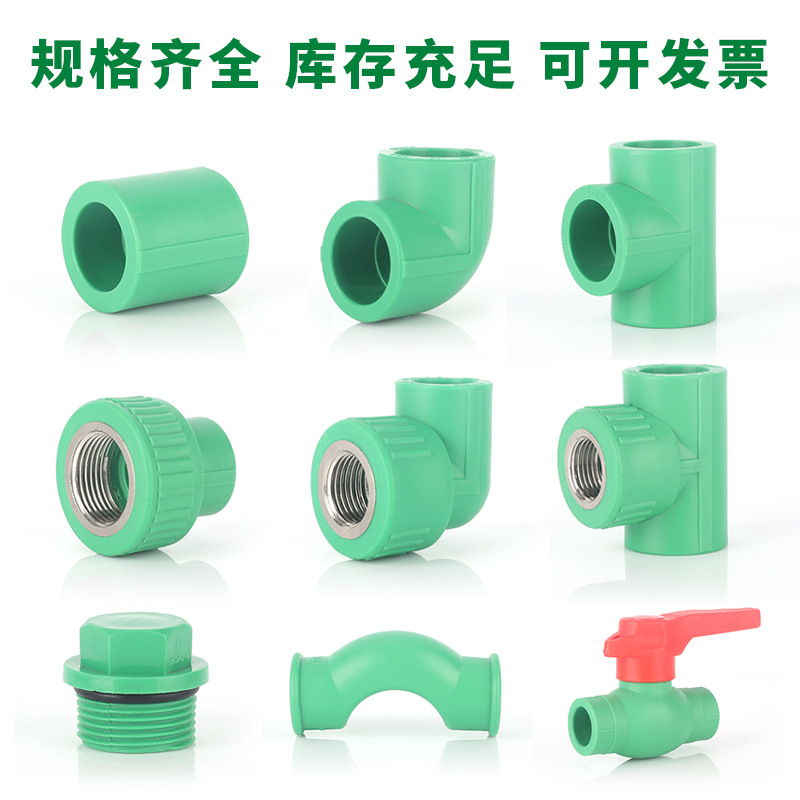

Reliable PPR Water Pipe Connectors: Inner Wire Tee, 4-Point & 6-Point Fittings for Durable Plumbing Solutions

In the ever-evolving world of modern plumbing, durability, efficiency, and ease of installation have become the driving forces behind material and component selection. Among the most trusted solutions today are PPR (Polypropylene Random) water pipe connectors. With innovative designs like the Inner Wire Tee, 4-Point, and 6-Point fittings, PPR systems offer a reliable, long-lasting, and user-friendly alternative to traditional metal piping. Whether you're a professional contractor or a DIY enthusiast, these connectors are transforming the way we think about plumbing.

Evolution of Plumbing Systems: Why PPR Stands Out

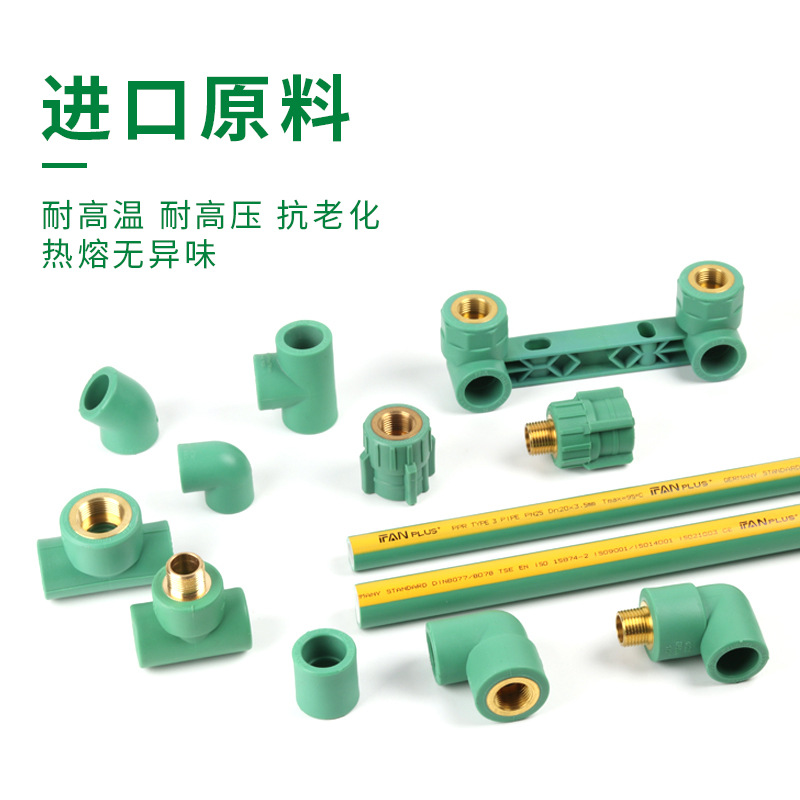

For decades, metal pipes were the standard in residential and commercial construction. However, they came with significant drawbacks—corrosion, heavy weight, and complex installation processes. As the demand for more sustainable and efficient building materials grew, PPR pipes quickly gained traction in the industry. Known for their resistance to high temperatures, chemical stability, and ease of installation, PPR systems have become the go-to choice for modern plumbing needs.

At the heart of these systems are the connectors that ensure structural integrity and seamless flow. Unlike traditional threaded or flanged joints, PPR connectors rely on heat fusion technology, creating a leak-proof and long-lasting bond. Among the most popular options are the Inner Wire Tee, 4-Point, and 6-Point fittings—each designed to meet specific performance and installation requirements.

Understanding the PPR Connector Family

The versatility of PPR connectors lies in their diverse designs, each tailored for specific applications. The Inner Wire Tee is a critical component for branching water lines without compromising structural strength. Its reinforced internal threading ensures a secure connection, making it ideal for both hot and cold water distribution systems.

For faster installations, especially in tight spaces, the 4-Point Direct Outer Wire Elbow offers a streamlined solution. This connector allows for quick alignment and secure fitting without the need for additional tools or adjustments. Its design minimizes resistance and ensures smooth water flow, which is crucial in high-efficiency systems.

When it comes to handling high-pressure environments, the 6-Point PPR Fittings deliver unmatched reliability. With six reinforced contact points, these connectors provide superior load distribution, reducing the risk of leaks or failures under stress. They are commonly used in multi-story buildings and industrial applications where consistent water pressure is essential.

The Power of Heat Fusion: Why It Matters

One of the defining features of PPR systems is the use of heat fusion technology. Unlike traditional methods that rely on seals or threads, heat fusion creates a molecular bond between the pipe and the connector. This process not only eliminates the risk of leakage but also ensures a seamless, joint-free system that is resistant to corrosion and wear.

Compared to threaded or flanged connections, heat-fused PPR fittings offer superior longevity and lower maintenance needs. They are also less prone to mechanical failure, making them ideal for concealed installations in walls and floors. However, proper training and technique are essential to ensure a perfect bond. Users must follow recommended temperature and pressure settings during the melting process to achieve optimal results.

Built for Professionals and DIYers Alike

PPR connectors have earned widespread adoption across both commercial and residential sectors. Large-scale construction companies appreciate the speed and reliability of PPR systems, often opting for bulk purchases to streamline their plumbing workflows. The ability to install large sections quickly without compromising quality makes these connectors a cost-effective solution for high-volume projects.

At the same time, DIY enthusiasts are discovering the ease of working with PPR fittings. Whether it's upgrading a bathroom or renovating a kitchen, homeowners can achieve professional-grade results with minimal tools. The lightweight nature of PPR components and the simplicity of heat fusion make them accessible to users without advanced plumbing experience.

Key Considerations When Choosing PPR Connectors

Not all PPR connectors are created equal. When selecting the right fittings for your project, consider the following factors:

- Material Quality: Look for connectors made from high-grade polypropylene that can withstand high temperatures and resist chemical degradation.

- Structural Design: Ensure the fittings are engineered to handle the pressure demands of your specific application, especially in multi-story or high-rise buildings.

- Compatibility: Choose connectors that support a range of pipe diameters and configurations to accommodate diverse plumbing layouts.

The Future of Plumbing: Smart and Sustainable

As the construction industry moves toward smarter, more sustainable practices, PPR connectors are poised to play a vital role. Their compatibility with energy-efficient systems, low environmental impact, and recyclability make them a natural fit for green building initiatives.

Moreover, with the rise of smart homes and intelligent water management systems, PPR connectors are being adapted to integrate seamlessly with IoT-enabled plumbing devices. This evolution promises greater control, real-time monitoring, and enhanced water conservation—key pillars of future-ready infrastructure.

Conclusion: Building a Better Future with PPR Connectors

In a world where efficiency, durability, and sustainability are more important than ever, PPR water pipe connectors offer a compelling solution for modern plumbing needs. Whether you're working on a large-scale construction project or a simple home renovation, these fittings provide the strength, flexibility, and reliability required for today’s demanding environments.

From the robust Inner Wire Tee to the high-performance 6-Point fittings, each connector plays a vital role in ensuring a seamless and leak-free system. As the industry continues to evolve, PPR technology will remain at the forefront—delivering smarter, cleaner, and more efficient plumbing solutions for generations to come.