Premium PPR Water Pipe Connectors: Inner Wire Tee & Outer Wire Elbow Fittings for Reliable Plumbing Solutions

Buried in the Walls, Yet Indispensable: The Silent Heroes of Modern Plumbing Systems

Imagine turning on your kitchen faucet or stepping into a warm shower, never giving a second thought to how the water arrives exactly where you need it. Behind the walls and beneath the floors lies a network of components working tirelessly to ensure seamless water flow. Among these unsung heroes are the PPR water pipe connectors—specifically, the inner wire tee and outer wire elbow fittings. These seemingly small elements play a crucial role in maintaining the integrity and performance of any modern plumbing system.

Why PPR? A Revolution in Material Innovation

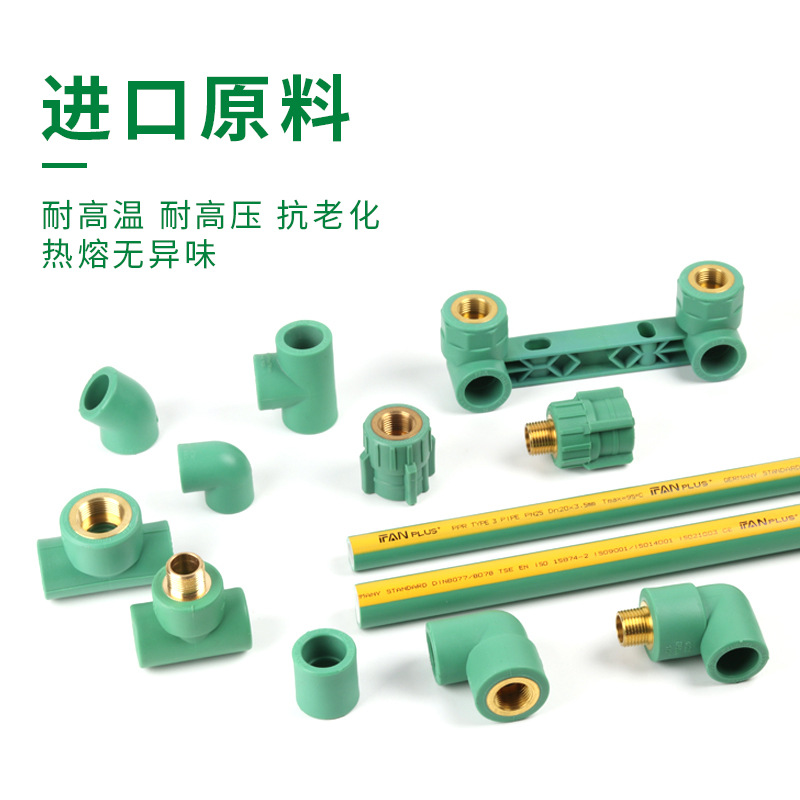

PPR, or random copolymer polypropylene, has transformed the plumbing industry with its remarkable properties. Unlike traditional metal pipes that corrode over time, PPR fittings offer unmatched durability, resistance to chemical degradation, and complete safety for potable water systems. They are also incredibly lightweight and easy to install, reducing both labor time and energy consumption during construction. As the world moves toward greener building practices, PPR has become the material of choice for architects, engineers, and homeowners alike.

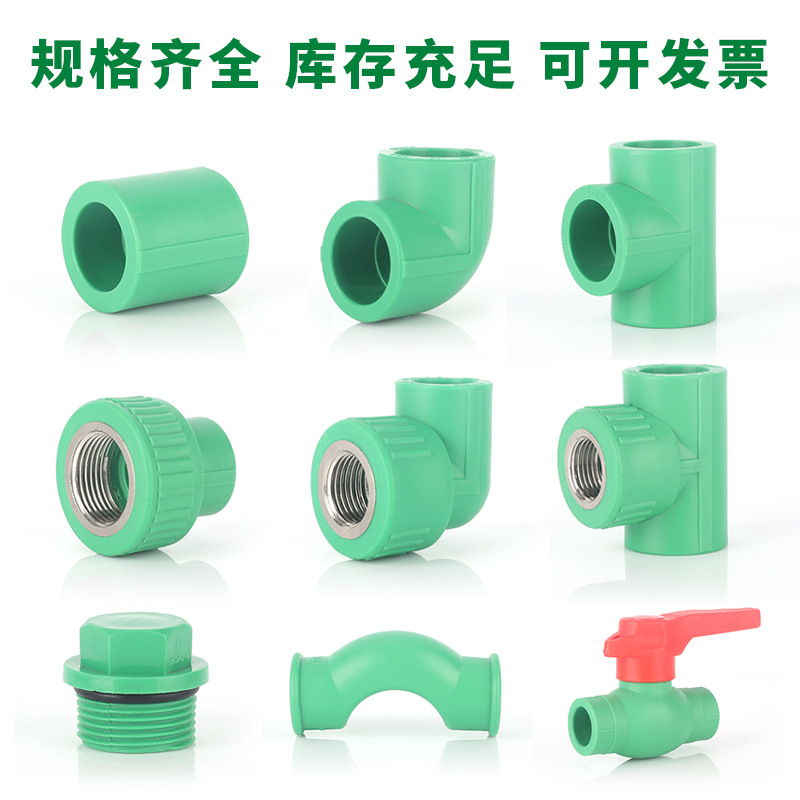

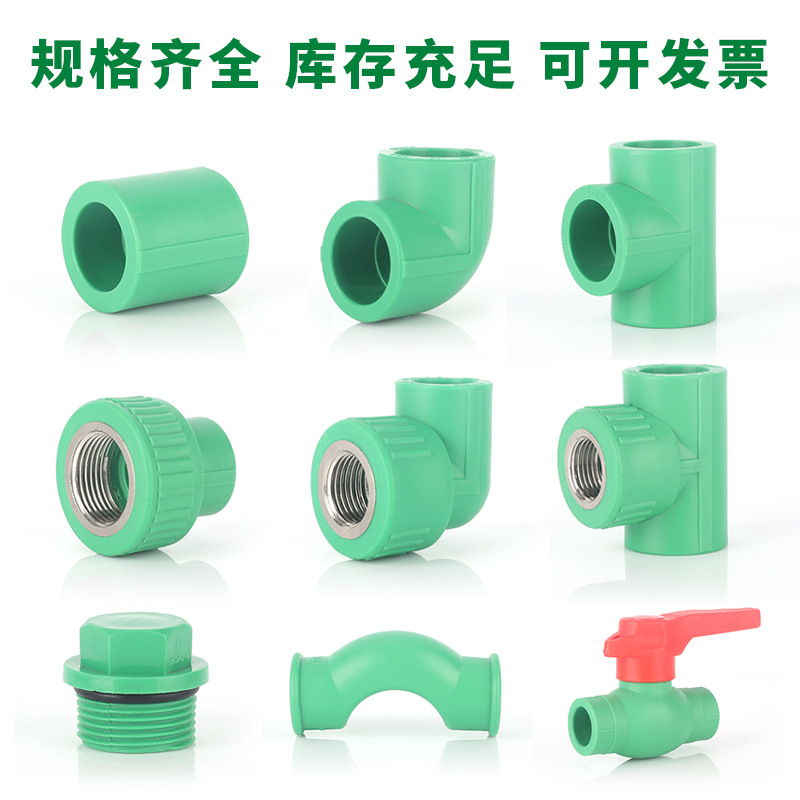

Inner Wire Tee & Outer Wire Elbow: Small Pieces, Big Impact

The inner wire tee and outer wire elbow fittings may appear simple, but their functionality is anything but. The inner wire tee allows a branch to be created from a main pipeline, ensuring water can reach multiple fixtures simultaneously without pressure loss. Meanwhile, the outer wire elbow enables smooth directional changes—whether in tight corners or complex layouts—without compromising flow efficiency. These fittings are essential for managing the invisible forces of water pressure and flow, turning potential chaos into a well-orchestrated system.

Behind the Scenes: The Craft of Precision Manufacturing

High-quality PPR fittings are not simply molded and shipped—they undergo rigorous manufacturing processes to ensure every detail meets exacting standards. From injection molding precision to the strength of internal and external threads, each component is designed to withstand decades of use. Superior sealing surfaces and anti-aging properties ensure that these connectors won't crack, leak, or degrade under normal conditions. In contrast, low-quality fittings can lead to costly leaks, structural damage, and frustrating rework—problems that can easily be avoided by choosing trusted PPR products.

Perfect for Homes and High-Rises: Versatility Across Applications

Whether you're renovating a small bathroom or designing the plumbing for a commercial high-rise, PPR connectors offer unmatched versatility. For residential use, these fittings are ideal for kitchens, bathrooms, and underfloor heating systems where flexibility and reliability are key. In commercial settings like hotels, office buildings, and hospitals, they support large-scale installations that demand minimal maintenance and long-term performance. Choosing the right type of connector for each application ensures optimal flow, easy access for future repairs, and overall system longevity.

Installation to Inspection: Making the Most of Your PPR Connections

Proper installation is crucial to the success of any PPR system. These fittings are typically connected using a hot-melt technique that requires precise temperature control and clean, aligned joints. A slight misalignment or improper heating can compromise the entire system. Once installed, regular inspections are recommended to catch early signs of wear or leakage. By following best practices during installation and staying vigilant during maintenance, users can ensure their PPR plumbing system delivers reliable service for decades.

Debunking Myths: Clearing the Fog Around PPR Fittings

Despite their widespread use, several misconceptions about PPR fittings persist. Some believe that plastic fittings are inherently weaker than metal, but PPR’s resistance to corrosion and scale buildup makes it more durable in the long run. Others assume that cheaper fittings offer the same performance, but subpar products often fail prematurely, leading to expensive repairs. Finally, while PPR installation is straightforward, it still requires professional tools and technique—cutting corners can lead to serious issues down the line.

Looking Ahead: How PPR Technology is Shaping the Future of Water Systems

As smart homes and intelligent building systems become the norm, PPR fittings are evolving to meet new demands. Their compatibility with advanced monitoring systems and eco-friendly insulation materials makes them ideal for next-generation plumbing. Imagine a future where your water system is not only leak-free and efficient but also seamlessly integrated with home automation—alerting you to issues before they become emergencies. With PPR at the core, this future is closer than you might think.