Premium PPR Water Pipe Connectors: Inner Wire Tee, 4-Point Direct & 6-Point Outer Wire Elbow Fittings for Hot Melt Plumbing Systems

When it comes to plumbing, the integrity of a system often hinges on one crucial element — the connectors. A single faulty joint can lead to costly leaks, inefficiencies, and even structural damage. This is where high-quality PPR water pipe connectors step in, transforming the way both professionals and DIY enthusiasts approach modern plumbing. Designed specifically for hot melt systems, these fittings ensure durability, precision, and long-term reliability.

From Kitchen Leaks to Commercial Engineering: Why the Right Fitting Makes All the Difference

Whether you're dealing with a dripping kitchen faucet or overseeing a large-scale commercial plumbing project, the choice of pipe connectors plays a defining role in system performance. Traditional systems often suffer from corrosion, leakage, or poor sealing, especially under high pressure or temperature changes. That’s where PPR (Polypropylene Random) piping systems have gained prominence in modern construction — offering a lightweight, corrosion-resistant, and thermally stable solution.

At the heart of this innovation are premium PPR water pipe connectors — engineered to deliver seamless integration with hot melt systems. These connectors not only enhance the longevity of the installation but also streamline the assembly process, making them a top choice for residential and industrial applications alike.

Inside the World of PPR Connectors: Understanding the Key Components

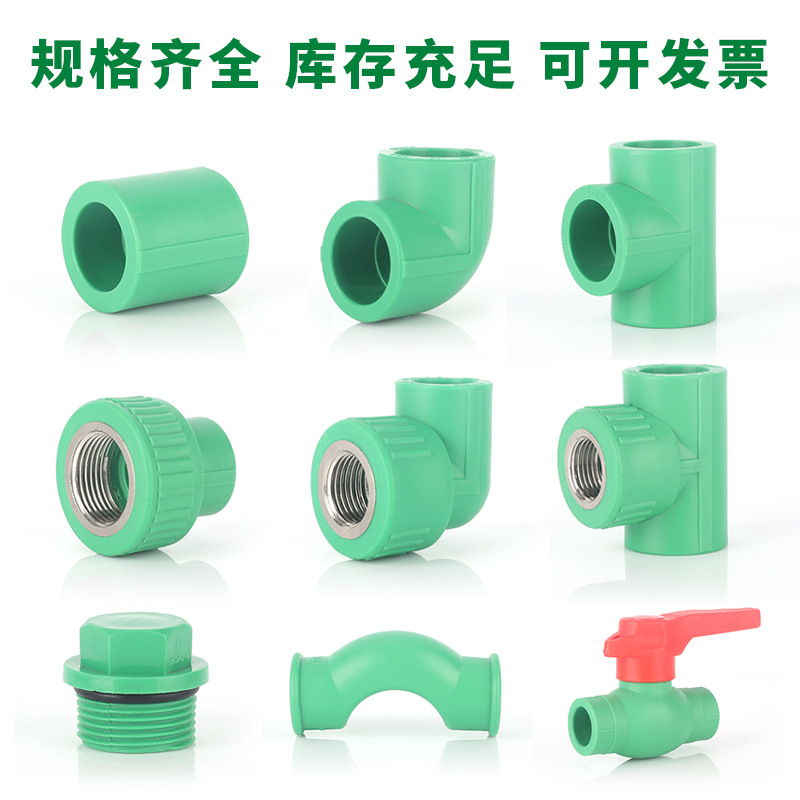

The versatility of PPR systems is largely due to the variety of fittings available, each designed for a specific function. Among the most essential are the inner wire tee, 4-point direct fitting, and the 6-point outer wire elbow — each contributing uniquely to the overall system’s performance.

The inner wire tee is a directional connector that allows branching of the water flow in three directions. It’s particularly useful in complex piping layouts where multiple lines converge. Its internal threading ensures a secure fit and prevents misalignment during installation.

The 4-point direct fitting is often considered the backbone of a stable PPR system. Its four contact points ensure even pressure distribution, minimizing the risk of leaks and making it ideal for straight-line connections where reliability is non-negotiable.

For situations that require a change in direction, the 6-point outer wire elbow shines. Designed to handle higher pressure environments, this fitting allows smooth directional transitions without compromising structural integrity. Whether you're routing pipes around corners or through tight spaces, this elbow fitting ensures a secure and leak-free connection.

Why Hot Melt Connection is Taking Over Traditional Methods

Hot melt technology has revolutionized the way PPR pipes and fittings are joined. Unlike traditional threaded or welded connections, which can weaken over time or introduce contaminants into the water stream, hot melt joints create a seamless, leak-proof bond. The process involves heating both the pipe and the fitting to a specific temperature, then joining them together to form a permanent, integrated connection.

Compared to older methods, hot melt connections offer several distinct advantages. They eliminate the need for additional sealing materials like O-rings or adhesives, reduce the risk of corrosion, and ensure a longer service life. Moreover, because PPR materials are inherently resistant to scaling and chemical degradation, the entire system remains clean and efficient for years to come.

Why Professionals and DIYers Trust Our PPR Fittings

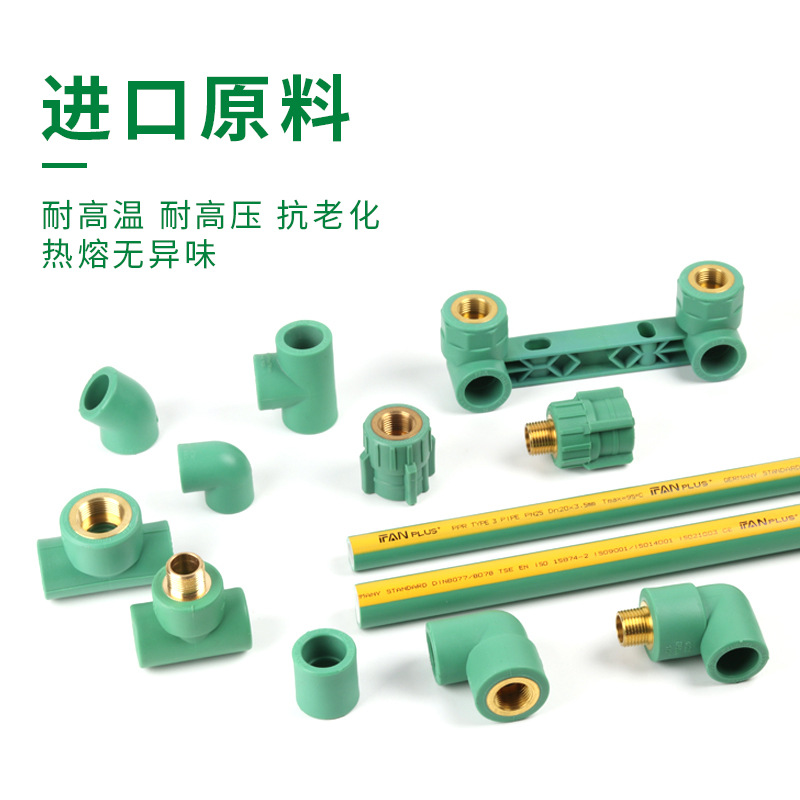

What sets our PPR water pipe connectors apart is the combination of superior materials and precision engineering. Each fitting is crafted from high-density polypropylene random (PPR) and reinforced with metal components for added strength and durability. This hybrid construction ensures that the fittings can withstand high temperatures and pressures while maintaining their shape and integrity over time.

Manufactured using advanced molding techniques, these fittings are free from burrs and imperfections, making them easy to install and compatible with a wide range of tools. Users consistently report reduced installation time and fewer errors, which translates to cost savings and increased productivity — whether you're a contractor handling a large-scale job or a homeowner tackling a weekend project.

Choosing the Right Fitting for Your Project

Selecting the appropriate PPR fitting is crucial for ensuring system performance. For smaller DIY tasks, the 4-point direct fitting offers a balance of simplicity and strength, making it an excellent starting point. In contrast, large commercial installations often benefit from the superior pressure resistance of the 6-point outer wire elbow and the versatility of the inner wire tee.

If your project involves hot water distribution, it’s essential to prioritize fittings with high thermal resistance. Look for PPR connectors that are certified for use in high-temperature environments and feature tight sealing mechanisms. For future maintenance, consider fittings that allow for easy disassembly or are compatible with existing systems to minimize downtime and replacement costs.

Installation Tips for Long-Lasting Connections

While PPR fittings are designed for ease of use, proper installation is key to achieving optimal performance. Always use a calibrated hot melt tool and ensure the temperature is set correctly — typically around 260°C. Clean both the pipe and fitting before heating to remove any dust or debris that could compromise the bond.

One common mistake is overheating the materials, which can lead to deformation or weak joints. Insert the pipe into the fitting with a firm, straight motion — avoid twisting, as this can create stress points. After installation, allow the joint to cool completely before testing. A simple pressure test using water or air can help confirm the integrity of the connection before the system goes live.

Regular inspections are also recommended, particularly in high-pressure or high-temperature environments. Look for signs of wear, leakage, or physical damage, and replace any compromised fittings promptly to avoid larger issues down the line.

Why Buying in Bulk Makes Sense

For contractors, plumbers, and bulk buyers, investing in a comprehensive set of PPR fittings can offer significant advantages. Purchasing in volume not only reduces the per-unit cost but also ensures consistency across installations, minimizing compatibility issues and reducing the need for last-minute sourcing.

Our fittings are produced under strict quality control standards, guaranteeing uniformity and reliability in every batch. For businesses, this means fewer callbacks, higher customer satisfaction, and the ability to complete projects more efficiently. For DIYers, pre-packaged kits containing inner wire tees, 4-point direct fittings, and 6-point elbows offer a cost-effective way to tackle multiple projects without overbuying.