Understanding Hot Melt Techniques

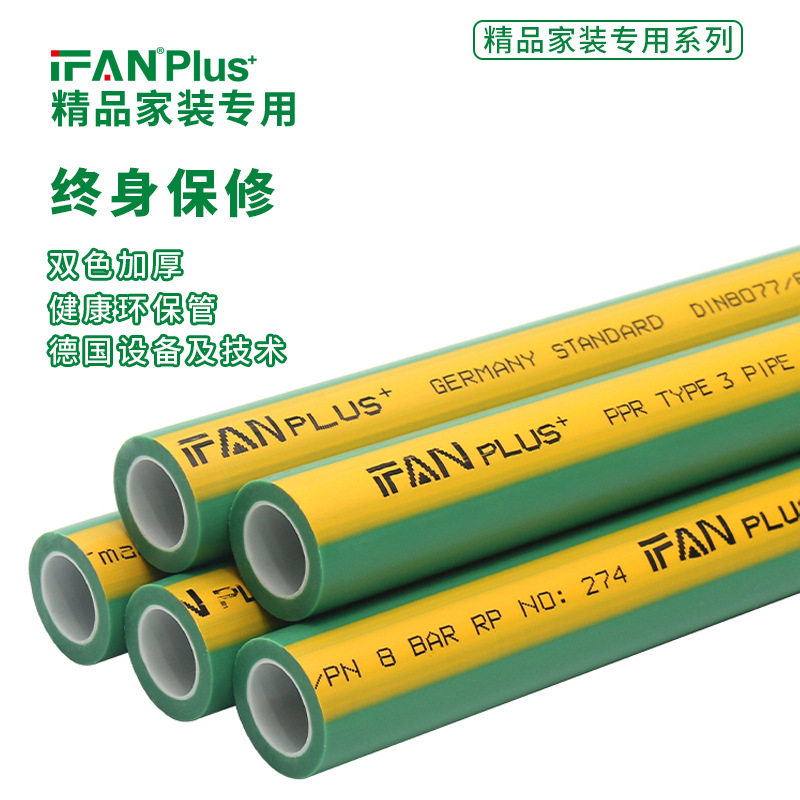

The process of using hot melt techniques in plumbing involves heating the ends of plastic pipes until they become soft and malleable before pressing them together to create a seamless, durable joint. This method is particularly favored when working with Polypropylene Random Copolymer (PPR) pipes such as those offered by IFAN due to their compatibility and efficiency.

Definition and Significance

Hot melt methods in plumbing involve utilizing heat to fuse pieces of pipe together without the need for adhesives or solvents. This technique provides an incredibly secure bond that enhances the integrity of the entire plumbing system. For IFAN PPR pipes, hot melt techniques ensure robust performance for both hot and cold-water applications.

PPR pipes are known for their durability, resistance to chemicals, and ability to withstand high temperatures. Using hot melt techniques ensures these qualities are not compromised during installation, granting homeowners peace of mind about the longevity and reliability of their water systems.

Basic Principles

Hot melt techniques work on the principle of thermofusion. When the PPR pipe ends reach the optimal melting temperature, the material becomes sufficiently soft to allow fusion. The molecular structures of the heated pipe surfaces intermingle, creating a solid bond upon cooling. No additional substances are required, making this method clean, efficient, and highly effective.

The science behind this fusion process ensures that the joined sections become one unified piece of piping, drastically reducing risks of leaks and weaknesses at connection points.

Preparing for Installation

Tools and Materials Required

Before beginning the installation, gather all necessary tools and materials:

- Hot melt tool (fusion machine)

- Measuring tape

- Pipe cutter

- Marking pen

- Cleaning cloths

- Gloves and protective goggles

- Recommended IFAN PPR pipes and fittings

Safety Precautions

Your safety should always be a top priority. Ensure you have the following gear and adhere to these guidelines:

- Wear heat-resistant gloves and protective goggles to prevent burns and eye injuries.

- Work in a well-ventilated area to avoid inhalation of any fumes.

- Keep flammable materials away from the workspace.

- Follow the manufacturer’s instructions for operating the hot melt tool.

Step-by-Step Installation Guide

Initial Setup

Begin by measuring the length of the PPR pipes needed for your project. Use a pipe cutter to cut the pipes to the desired lengths accurately. Next, thoroughly clean the pipe ends using cleaning cloths to ensure no dirt or moisture can affect the quality of the weld.

Heating Process

Set up the hot melt tool according to the manufacturer's instructions and allow it to reach the recommended temperature for IFAN PPR pipes. Typically, this would be around 260°C. Insert the pipe ends into the respective sockets of the heating tool and wait until they are properly heated and softened.

Joining the Pipes

Once the pipe ends are adequately heated, remove them from the hot melt tool and swiftly align and connect them. Apply consistent pressure to ensure the two ends fuse seamlessly. Hold them in place till they start cooling down and forming a secure, leak-proof joint.

Tips for a Successful Installation

Common Mistakes to Avoid

During installation, steer clear of the following mistakes:

- Avoid overheating or underheating the pipes which can lead to weak joints.

- Ensure proper alignment; misalignment can cause leaks and reduce system efficiency.

Best Practices

For best results, maintain even pressure while joining the pipes and refrain from moving the pipes prematurely. Allow adequate time for the fused joint to cool completely before subjecting it to water flow or pressure.

Maintenance and Troubleshooting

Regular Checks

Periodically inspect all joints and connections for any signs of leakage. Early detection of potential issues ensures timely repairs and prevents extensive water damage.

Additionally, follow routine maintenance practices such as flushing the system occasionally to remove debris and ensuring that temperature settings within the household do not exceed recommendations for PPR pipes.

Addressing Issues

If you encounter any problems like leaks or reduced water flow, attempt to identify the source. In most cases, minor adjustments or resealing may suffice. However, if substantial issues arise, it's wise to consult a professional plumber to avoid further complications.

Advantages of Using Hot Melt Techniques

Durability and Reliability

Utilizing hot melt techniques for IFAN PPR pipes offers several long-term benefits including unparalleled durability and reliability. These methods ensure superior fusion for home water systems, capable of withstanding various conditions without compromising performance.

Cost-Effectiveness

By minimizing the risk of leaks and the need for frequent repairs, hot melt techniques provide significant cost savings over time. Moreover, the efficient installation process reduces labor costs, making it an economically sound choice for homeowners and professionals alike.

Final Thoughts

Have you recently employed hot melt techniques for installing IFAN PPR tap water pipes? Share your experiences and let us know how this method has worked for you. Your feedback and questions help us improve and assist others better. Join the conversation today!